william.gardner2017

New member

- Joined

- Mar 29, 2025

- Messages

- 3

- Reaction score

- 0

- Points

- 1

- My Lincoln

- 1977 Lincoln Continental Mark V Cartier Edition

Hello all,

This will be my first post on here, but I have used the forums many times when I have had trouble with something, so thank you all for the help.

As a quick back story, I purchased my Mark V in November of 2024. At the time of purchase, there were a couple of problems (carburetor was running rich, oil was leaking, and then some other things). For the next 5 months, I put a lot of work into fixing anything that I felt needed to be fixed. The car was ready to hit the road by May.

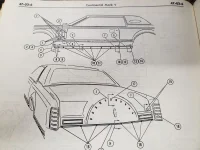

My Mark V was missing the optional rocker panel moldings at the time of purchase, but recently, I have acquired a pair of them. After cleaning and polishing them up, I attempted to install them. However, I am not seeing a specific place to hold them in place. I see a screw hole at the front of each (where the wheel well would be as well as what looks to be a hangar at the other end (however, the rust has mostly eaten away at it).

Now for the actual question. I was wondering if anyone knew how the rocker panel moldings were installed. I know I would screw it in at the front, but I am specifically wondering about installation along the entirety of the rocker panel (something like adhesive tape?). I am also open to ideas regarding another way to install them that wasn't used on the production line at Ford. Any help would be appreciated!

I can provide images if needed.

Thanks again!

William Gardner

This will be my first post on here, but I have used the forums many times when I have had trouble with something, so thank you all for the help.

As a quick back story, I purchased my Mark V in November of 2024. At the time of purchase, there were a couple of problems (carburetor was running rich, oil was leaking, and then some other things). For the next 5 months, I put a lot of work into fixing anything that I felt needed to be fixed. The car was ready to hit the road by May.

My Mark V was missing the optional rocker panel moldings at the time of purchase, but recently, I have acquired a pair of them. After cleaning and polishing them up, I attempted to install them. However, I am not seeing a specific place to hold them in place. I see a screw hole at the front of each (where the wheel well would be as well as what looks to be a hangar at the other end (however, the rust has mostly eaten away at it).

Now for the actual question. I was wondering if anyone knew how the rocker panel moldings were installed. I know I would screw it in at the front, but I am specifically wondering about installation along the entirety of the rocker panel (something like adhesive tape?). I am also open to ideas regarding another way to install them that wasn't used on the production line at Ford. Any help would be appreciated!

I can provide images if needed.

Thanks again!

William Gardner