What you have discovered is the California emission package versus 49 state.

1970 FLM vehicles built to be delivered into the CA market had an emission package that was different than the other 49 states. In the truck area on the left had a cylindrical metal piece that extended into the trunk. In essence a closed fuel system. Versus the other states that had a fuel tank vented to outside air.

With that said I have a 70 Mark III and it is a 49 state version so I do not have that feature.

Suggestions -

Get a vented gas cap

If you are going to install a vent into a fuel system that has none, do it in the fuel filler neck. And towards the top. NOT the tank! The replacement tank is expensive, hard to come by (yours is not exactly correct and was not designed for venting so leaks can occur.

I have never seen a fuel tank sender unit with a vent. I have seen some with a return line for conversions to fuel injection that require a return line. The mid-1960s Continental with 430/462 engine had a 3 ported fuel pump with a return line as well. That sender will not fit.

Not sure I under stand your #2

More on tank venting -

There are two times to vent the tank. When filling and when not filling

When filling the tank the filler neck should be large enough in diameter that air comes out when liquid fuel is going in. Mostly because the gasoline station hose nozzle is regulated to be smaller in diameter to comply with Federal Regulation for unleaded fuel. Your car pre-dates that and has a fuel filler neck that is fairly wide. You will know that you have issues is the nozzle clicks off and the tank is not full. The fuel is getting backed up in the neck. There is not much to modify to fix this venting need

Venting when not filling comes in two parts. When the vehicle is running and when it not running. However, the solution for both is the same. The need is far less because less ai movement is required.

If it were me, I would look for a vented gas cap. A pre-1970 cap may work for this. It is the simplest and easiest method to over come the issue. Your vehicle will be emitting fuel vapor with two down sides. It pollutes some. (And personally I don't care) and it exposes your fuel to air which does not matter unless the vehicle sits for years without use. That will break down the fuel faster. Which may be why the tank was replaced because moisture in the air condensed out, settled at the bottom of the tank and did it's corrosive number.

If you decide to install a vent for the tank in the fuel filler neck, cut the hole on the upside of the neck. The downside will have liquid fuel when filling. Loop any venting hose in a 360 circle so any water or dirt can not make the loop and get into the tank. If you want to make it more secure put some type of filter on the end.

Action

Hey Action, thank you for the response and information.

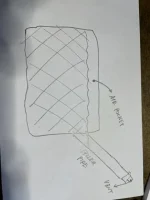

In regards to the vented gas cap I have two questions/concerns. From what I can discern "vented gas caps" come in two varieties. The first utilize an internal value to purge internal pressure from the tank and the second "vented gas caps" are vented via a hole with no value. Am I correct? Or do the value vented gas caps also allow atmospheric vent into the system as well? Secondly, and I've attached a photo to illustrate this potential issue, the filler pipe inlet on the gas tank comes from the side of the tank, thus there is a circumstance where, if vented through the gas cap, fuel will fill in the filler pipe creating an air pocket in the fuel tank. Is this something worth considering? I imagine this is why originally the tank was vented through the top of the fuel tank, attached photo. Also I've read fuel spillage can occur through the cap if vented, fuel tank full, and turning. Correct?

I originally assumed this replacement tank wasn't vented only to simplify production. You mentioned that this tank was not made to be vented. In your opinion then, just to clarify, you would not add any vent fitting to this fuel tank? FYI i would not be doing the welding, I found a good shop who I've spoken to who understand the problem and said they can weld a vent fitting on for me, pressure test, etc.

I'm not concerned about potential polluting, but I would like to minimize gas smell as much as possible. If in your experience with just having the vent with no canister doesn't create too much smell, then that's a great option. More to that thought, how were the non-california mark 3's vented? through the filler pipe? and where did they mount the vent?

Also, in general, in the service manual it states the vent canister also allowed expanded fuel to go somewhere. Is this something to consider? I dont believe this canister has any carbon in it. I believe it is just a baffled tank with a vent. Correct?

In conclusion these are my further questions:

1. If vented through cap: Correct vented fuel cap and potential air pocket problem, fuel expansion (should it be considered)

2. If vented through filler pipe: Mounting location (per non-california cars), similar air pocket problem as above, fuel expansion (should it be considered), process (weld fitting to run hose?)

3. If vented through the fuel tank: bad idea all together? type of venting (baffled canister (OE) or just a vent)?

Finally, I did pull the original canister off the car. Blew some compressed air through both ports and it did come out the other side. Is this canister good to go for reusing? I've been able to source after market baffled canisters, but obviously I would have to consider mounting and fitment and all that which could be avoided if I decide to go the canister route and can reuse the original.